LUM-6000 light curing cold inlaying machine

Main features:

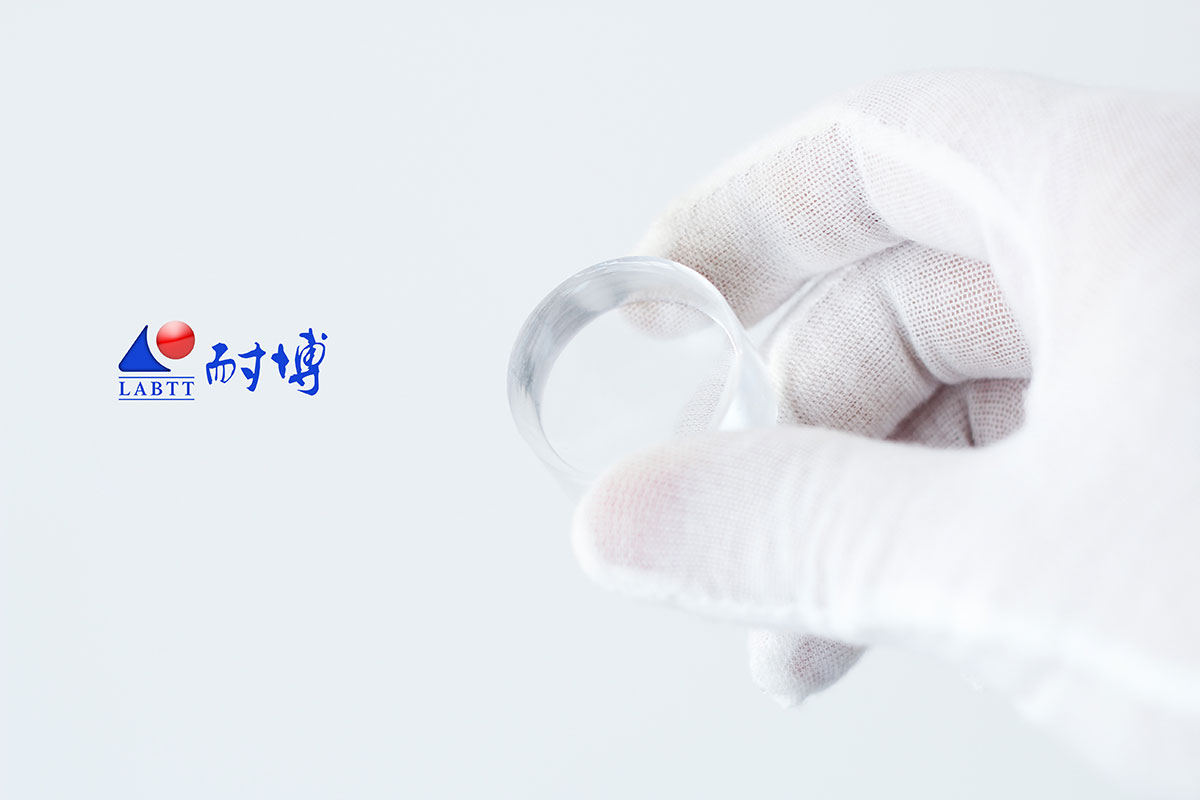

Light cured inlay has advantages such as fast speed, low viscosity, and transparency.

The LUM-6000 automatic light curing cold inlay machine uses dual wavelength LED lights, specifically designed for the light curing of light curing inlay materials.

Cold light source, no thermal radiation, low surface temperature rise of the subject, solving the problem of thermal damage during the inlay process.

Transparent light cured inlay fills the gaps in the sample, achieving a tight bonding between the sample and the inlay, thus providing good protection and support for the sample during grinding and polishing processes.

Technical parameters:

1. Dual wavelength combination: 365+395; (395+450, 365+450 optional);

2. The three brightness levels for each wavelength are independently set;

3. There are surface light sources and reflective films on six sides, including the upper and lower, left and right, front and back, which provide uniform illumination and high curing efficiency;

4. Manual/automatic working mode.

5.99 automatic working programs, according to the set wavelength, brightness, and lighting time.

6. The light panel can be easily replaced;

7. Ultra long service life: The service life is more than 10 times that of traditional mercury lamp curing machines, and the service life is not affected by the number of switches;

8. Low energy consumption, only 10% of the power consumption of UV curing machines (mercury lamps), can save 90% of electricity;

Vacuum pumping device to further reduce bubbles (optional).