LC-250L metallographic wire cutting machine

Super Large Automatic Metallographic Cutting Machine

Main features:

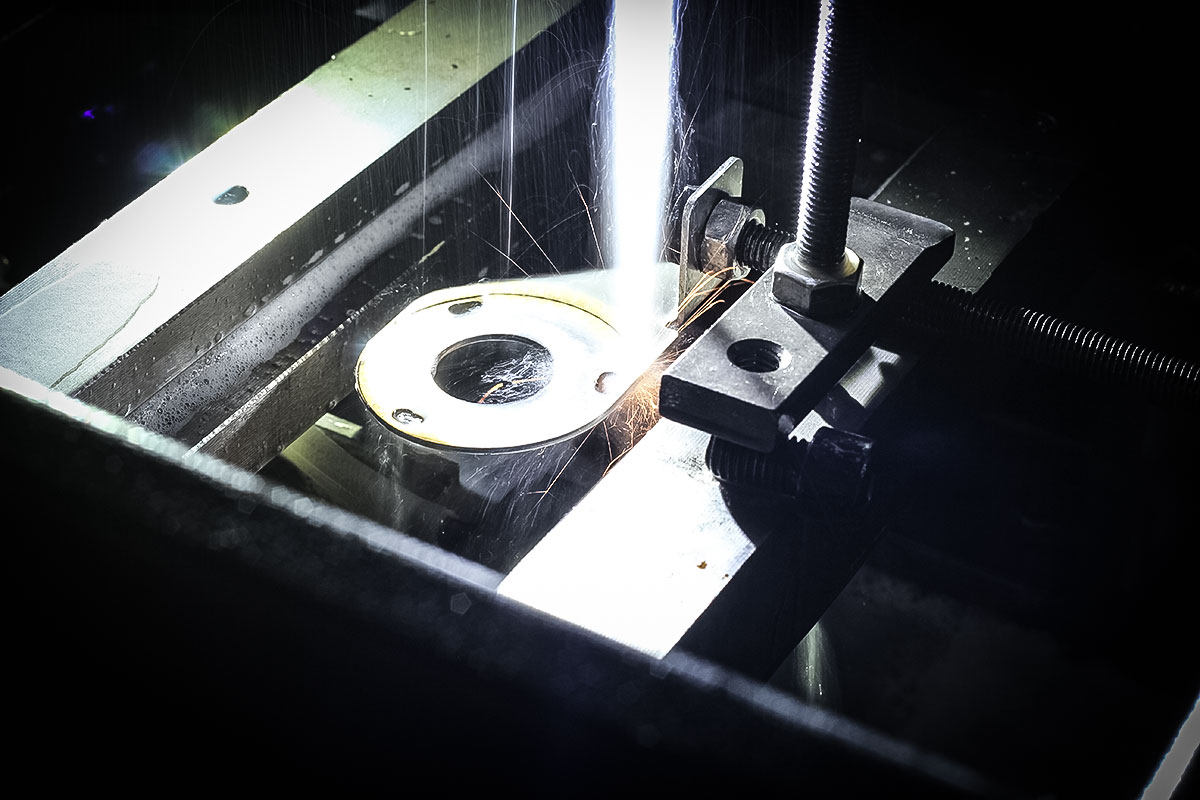

LC-250L metallographic wire cutting machine adopts wire cutting method to cut metallographic samples with low noise, simple operation, safety and reliability. In modern laboratory, it can partly replace the metallographic cutting machine of grinding wheel.

1. The cutting speed is fast, reaching 9500mm2/H.

2. When cutting workpieces of different materials and thicknesses, the parameters are automatically adapted without manual adjustment.

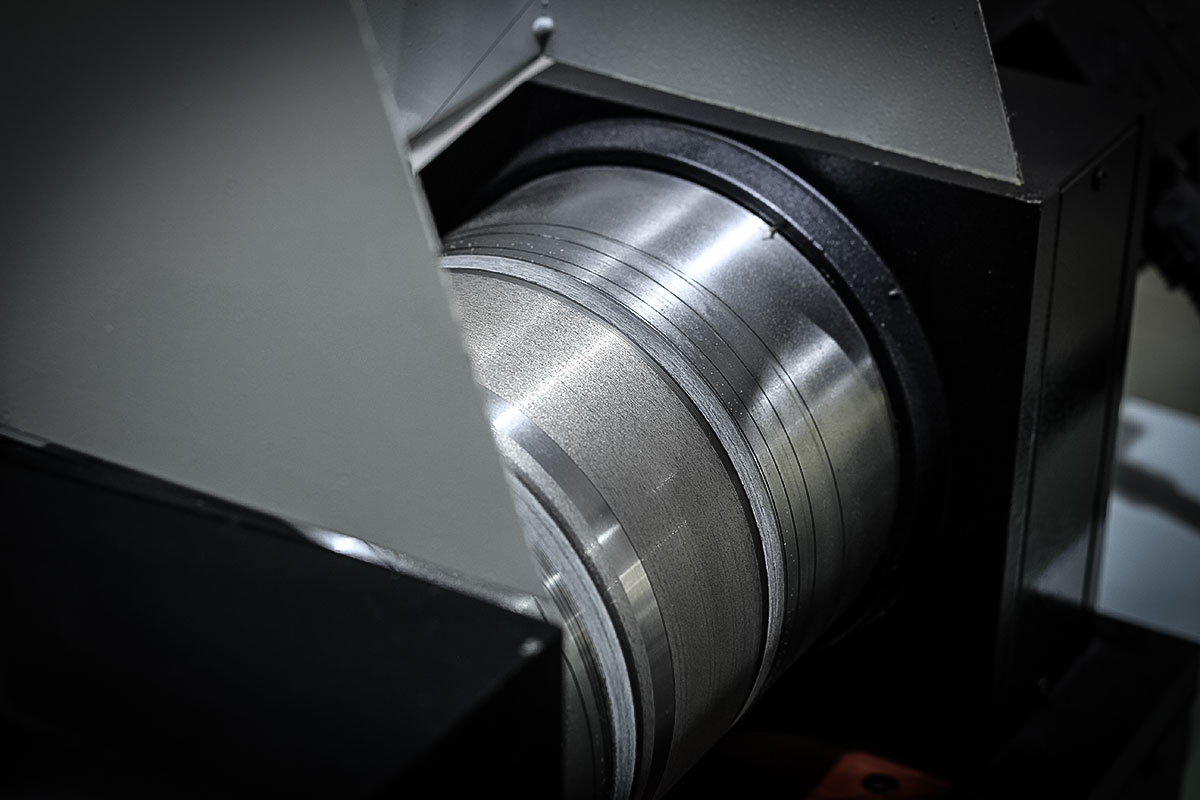

3. The lead screw adopts precision ball screw, with guaranteed long-term accuracy and wear resistance.

4. The up-down verticality of the wire frame structure is good, saving time and labor.

5. The body is made of casting, which is stable and shock absorbing.

6. The control cabinet is fully enclosed to ensure that the electric cabinet is free of dust and oil after several years of use, so as to improve the service life of the electric cabinet.

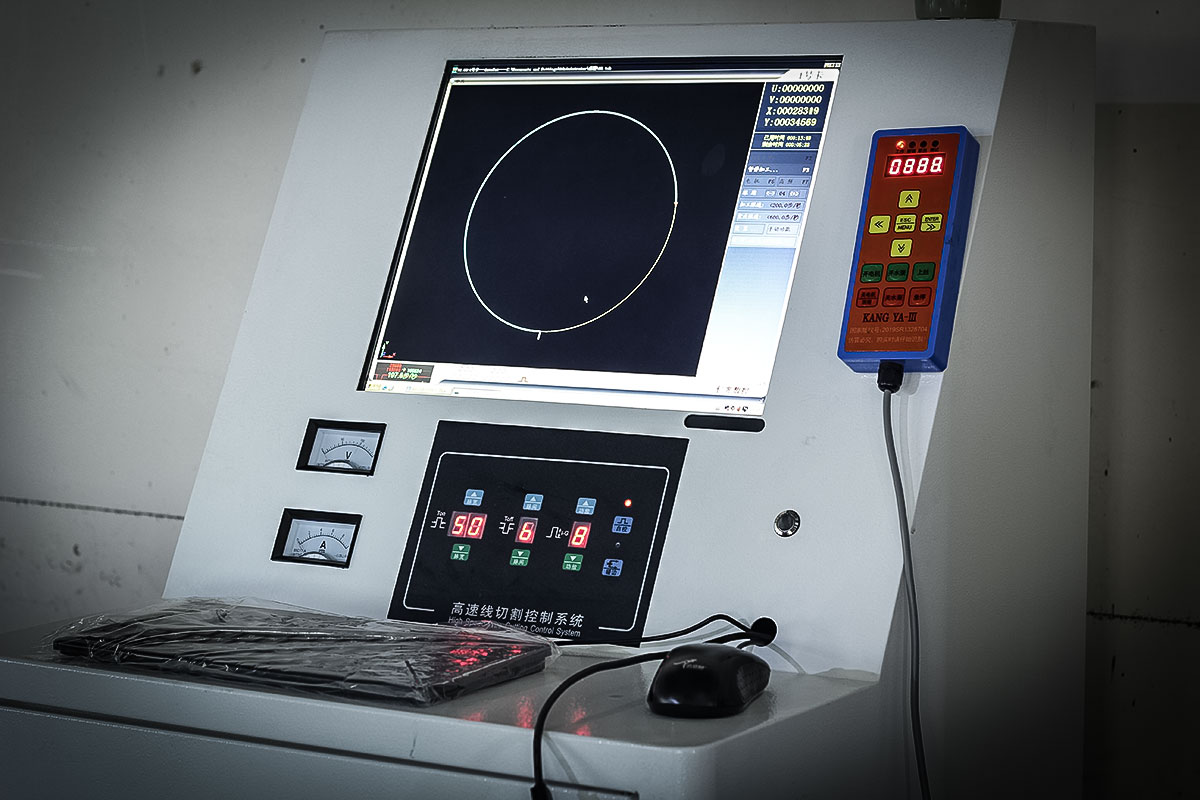

7. The special software for metallographic line cutting is used as the programming software, and the program is written directly in the software.

8. The oil pump system is added with an oil distributor to ensure the screw rod and X The lubricating oil circuit of Y-axis lead screw arrives at the same time, saving fuel and time.

9. The paint of sheet metal adopts baking process, which has strong adhesion, corrosion resistance, scratch resistance and is not easy to fall off.

10. Environment friendly LED work light, beautiful, power saving and durable.

Technical Parameter

Model LC-250L

Cutting speed reaches mm2/H 9500

Processing precision mm ± 0.01

Cutting surface roughness μ m Ra≤2.5

Minimum feed increment 0.001 mm

Worktable size mm 300 × four hundred

Worktable stroke (X * Y) mm 200 × two hundred and fifty

Z-axis stroke mm 220

Maximum cutting slope/workpiece thickness mm ± 3 °/80

Normal/maximum cutting current at A 4-6/9

Wire speed m/s 0-12m/s, adjustable by frequency conversion

Diameter of electrode wire mm Φ 0.10-0.22

Molybdenum wire loss 160mm2/min, continuous cutting 150000 mm2, wire loss ≤ 0.01 mm

Water tank volume 50L

Input voltage 220-380V/AC ± 10% 50-60Hz

Power KVA 2

Maximum bearing kg 2520

Main engine weight kg 800

Weight of electrical control cabinet kg 80kg

Boundary dimension of electrical control cabinet mm 600 × seven hundred × one thousand and three hundred

Packing size of main machine mm 1000 × nine hundred × one thousand and three hundred