LC-350YAZ Metallographic cutting machine

Metallographic Cutting Machine

Main features:

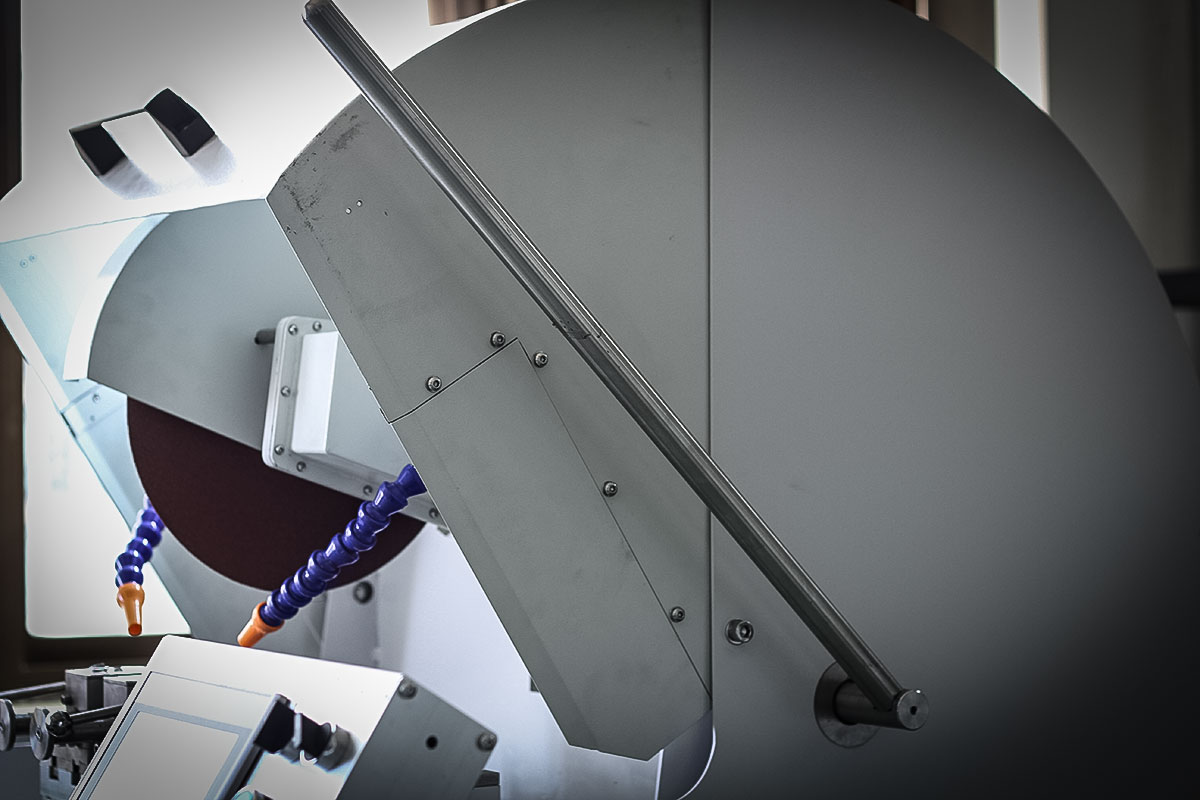

1. The machine adopts fully enclosed structure, with good sealing effect, safety and reliability;

2. Electrical appliances such as motors are separated from the cutting room, so the equipment is safer and the electrical appliances have longer service life;

3. The right hand pull rod and the cutting blade can easily cut downward;

4. The front hand wheel can control the forward and backward movement of the worktable with stable feeding, and the rear motor can automatically control the forward and backward movement of the worktable with feeding;

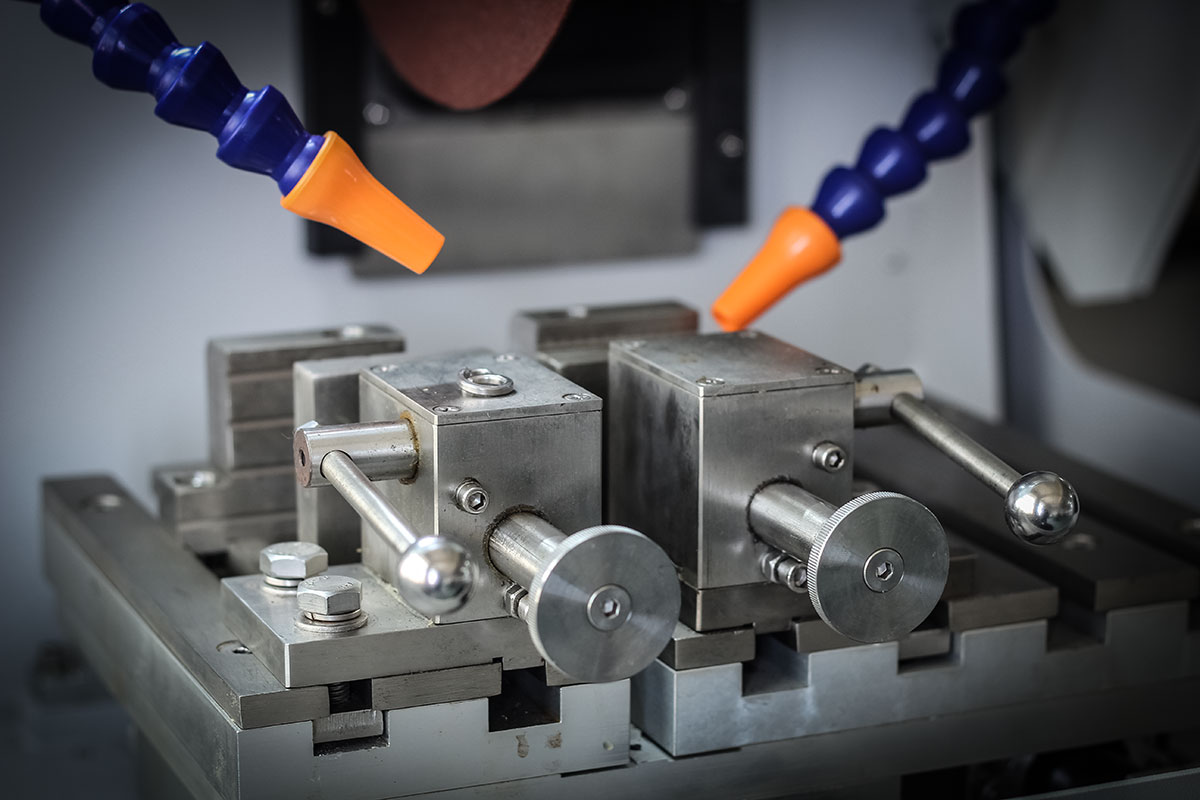

5. The cutting pieces can be fixed at different heights and at different front and rear positions of the workpiece, and the combination of different positions can complete large size cutting;

6. The upper part of the equipment is completely covered by a protective cover that can be opened and closed. The large observation window on the protective cover is used in conjunction with the high brightness lighting system. The operator can master the cutting process at any time;

7. The machine adopts a quick clamping device, which can clamp objects more quickly and accurately;

8. The worktable with groove is matched with the quick clamping device to meet the cutting of various special-shaped workpieces;

9. The super strong cooling system makes the workpiece not burn when cutting. The cooling water tank is placed in the equipment base, and there is a filter screen in the water tank to facilitate the collection of residues and scraps;

Technical Parameter

Name and specification

Cutting mode: chopping cutting, horizontal feed cutting (manual, automatic)

Grinding wheel specification 350 * 2.5 * 32

Rotating speed 2800r/min

Maximum cutting section Φ 100mm

Chopping up and down cutting distance 120mm

The cutting distance before and after parallel is 180mm

Motor 4KW 380V 50HZ