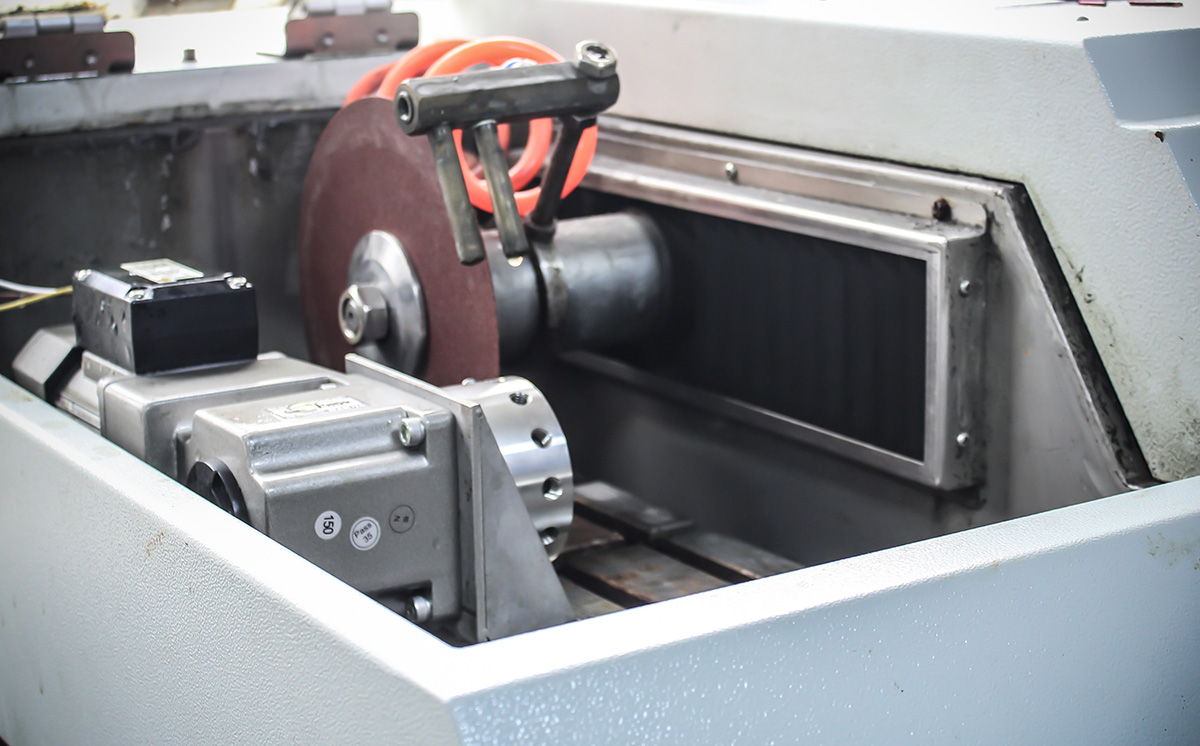

LC-200XP-R Automatic High Speed Precision Cutting Machine

Metallographic Cutting Machine

Main features:

-Adopt man-machine interface, PLC control, intuitive interface, simple operation.

-English and Chinese language can be switched simple operation, convenient parameter setting.

-Spindle adopts servo motor closed loop control, overload protection.

-There are two cutting ways to choose cutting, a wider range of materials to adapt to the cutting.

-Setting parameters can be saved. Different materials can be cut to select user to save parameters. There is no need to set parameters anew every time.

-There is external circulating water cooling device.

-Closed and transparent protective cover and safety switch provide protection for the operator.

The user interface:

1. Parameter setting

-Spindle speed: can be set between 500- 3000r/min (optional 500-5000r/min) to adapt to the material cutting, Stepless speed regulation is effective when the equipment is running

-Cutting stroke: range 0-200mm, set the appropriate stroke to finish cutting and stop cutting, continuous cutting of the same sample does not need new positioning.

-Cutting speed: range of 0.01-3mm/s, select the cutting speed suitable for the material to meet the cutting requirements of the material, Invalid setting while device is running.

-Backward speed: The range of 0-15mm/s refers to the speed of backing back to the starting point of cutting when the cutting is running to the set distance. The larger the setting, the faster the backing will be.

-Point move speed: the range of 0-15mm/s, refers to the manual forward and backward speed, the equipment operation is not skilled, should be set a small, to avoid the cutting piece hit the workpiece.

-Choice of cutting mode: direct cutting and impact cutting two modes for users to choose, a wider range of materials to meet the cutting

-Direct cutting:it is the common and most economical cutting mode, suitable for most material cutting options.

-Impact cutting: suitable for a specific material and a very high hardness of the cutting piece can not be found, and the worn material is easy to block the cutting piece, or the cutting piece of insufficient abrasive, impact cutting may lead to higher cutting piece wear, but will reduce the risk of overheating of the workpiece.

-Cutting distance: range 0.1-2mm, only effective for impact cutting mode, the smaller the distance set, the faster the impact cutting speed, and the speed is related to the set cutting speed.

-User parameters: when in use, we can set the parameters stored in the user parameters, in the same material cutting piece, for different samples and different materials we do not need to set the parameters every time, more convenient to complete the sample cutting.Save parameters can currently store 12 items, need to store more users need to add when purchasing instructions. (12 items show best)

2. User parameter interface:

The top row is the current setting parameter value and cutting mode, we can put the current parameter into the corresponding parameter number.

Parameter selection: Press the pull-down button and the parameter number will pop up. Select the corresponding parameter number. Read to the touch screen: reads the parameters set to the current.

Save Parameter: Select the parameter number to be saved before saving the parameter, and press "Save Parameter" to save it to the corresponding parameter number.

Fetch parameter: select the required parameter number and read the parameter number to the current one.

Technical Parameter

|

Item |

specifications |

|

Cutting disc |

Standard φ200 x 32 x0. 9mm |

|

Spindle speed |

500-3000r/min (optional 500-5000r/min) |

|

Feed speed |

0.01- 3 mm/s |

|

Manual feed speed |

0-15mm/s |

|

Backward speed |

0-15mm/s |

|

Impact cutting distance |

0.1- 2 mm |

|

Cutting stroke (Y axis) |

200mm |

|

Maximum cut diameter |

φ60 mm |

|

Maximum length clamping table |

150mm |

|

Maximum width clamping table |

200mm |

|

Servo motor |

Power: 1.1 kw |

|

Usage method data |

Can store 12 kinds |

|

Power supply: |

AC220V 50HZ |

|

Overall dimensions |

750 * 860 * 430 mm |

|

Weight |

126KG |

Standard accessories

|

Item |

Quantity |

Item |

Quantity |

|

Open end spanner (22-24, 17-19) |

1 |

Cooling system (including water tank, water pump, water inlet pipe and drainage pipe) |

1 |

|

6mm inner hexagon wrench |

1 |

Cutting fluid |

1 bottle (1L) |

|

5mm inner hexagon wrench |

1 |

Hose hoops 13 to 19 |

2 |

|

Power cord |

1 |

Hose hoops 40-63 |

2 |

|

Cutting piece (Φ200 diamond cutting disc) |

1 |

|

|